Scalers are essential instruments in dentistry. Scaling tools should hence be of high quality to provide excellent quality treatment. Scalers and curettes are instruments that come in use for removing subgingival and supragingival plaque and calculus from the surfaces of teeth and roots.

Poorly designed instruments perform inefficiently and consume loads of time for the operator. This makes the process inefficient and also sometimes may fatigue the hand of the operator. The quality, size, and type of the scaling instruments greatly determine the efficiency of the treatment. Other than that, it also determines the quality of the treatment provided to the patients.

Dental Curettes and Their Functions

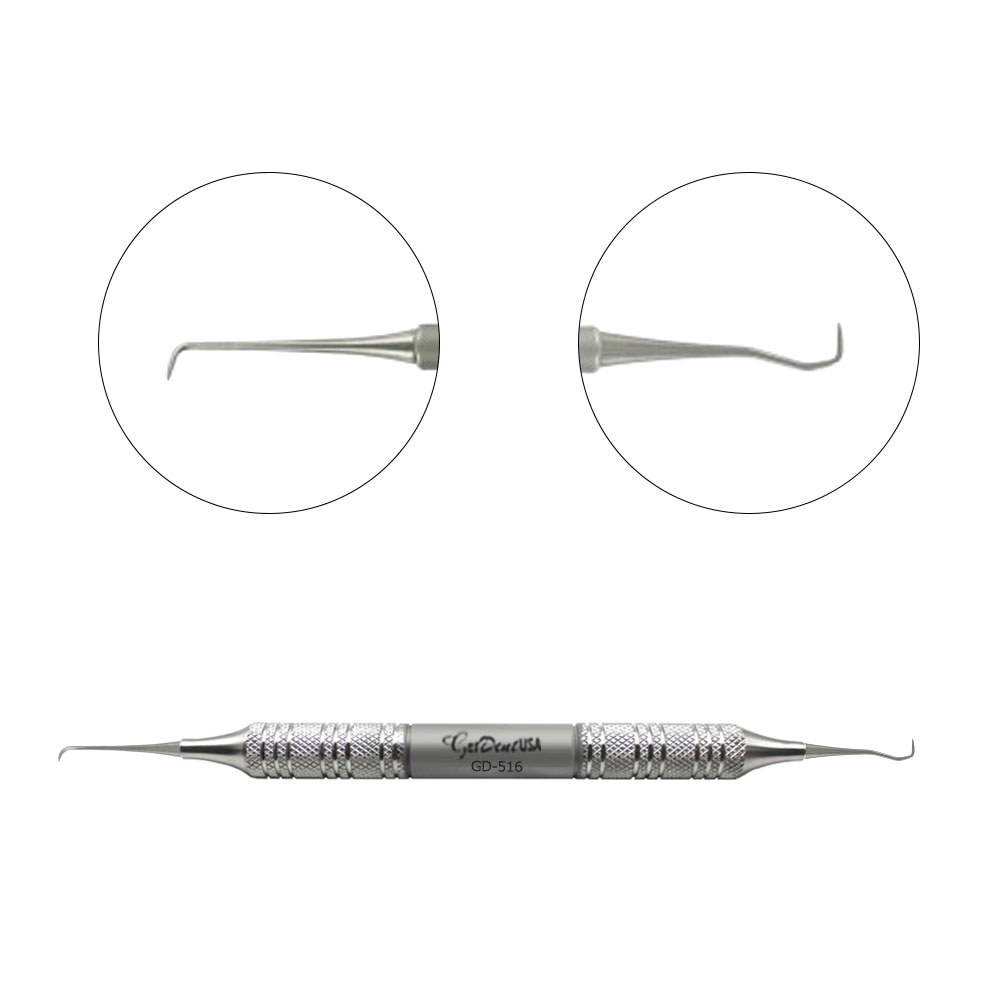

A curette is the type of instrument that comes in use for removing deep subgingival calculus. It also comes into use for root planning, removing altered cementum, and removing the soft tissues that line the periodontal pocket.

The cutting edge is on both sides of the blade and has a rounded toe. Curettes are finer than sickle scalers, and they do not have any other sharp points on their blades. Curettes can quickly go underneath the gingiva to pull out calculus with minimum soft tissue trauma.

In cross-section, the curette blade appears semicircular or spoon-shaped. Curettes are ideal instruments for subgingival scaling and root planning, as they adapt the best to complex root anatomy.

Scalers and Their Uses

Sickle Scalers are instruments that come in use for removing supragingival calculus. Sickle scalers have a flat surface and two cutting edges that converge to form a tip. The shape of the instrument is such that the tip does not break off during use. The design of the instrument is such that it is difficult to insert it underneath the gingiva.

Hence the instrument cannot come in use for subgingival scaling. Sickle scalers with straight shanks come in use for scaling anterior teeth, scalers with angled shanks come in use for posterior teeth.

Scalers and curettes come in different shapes and sizes. Some examples of scaler curettes are Cattoni scaler curette and Goldman fox scaler curette.

Sharp scaler bites into the calculus better than a blunt one. Scalers need to be sharpened whenever they are dull, or they start sliding against the calculus. The cutting edges of the scalers are made sharp by use of an Arkansas stone. A few drops of oil or water are put on the stone so the instrument can slide on it quickly. The second and third fingers rest on the side of the stone. This is for better control of the instrument. The cutting edge is rubbed on the stone, and the instrument is moved back and forth to sharpen it.

Some factors you should keep in mind while selecting scaling tools for your clinic:

Ergonomic Handle Designs:

The scalers should come with ergonomic handle designs; otherwise, operator arm fatigue is possible if heavy cleaning is required in the clinic. Hence, the instrument grasp should feel comfortable to the operator.

Sometimes, suppose the scaler is heavy and is uncomfortable to the operator. In that case, there is a high chance that the operator may develop carpal tunnel syndrome, which, if left untreated, can cause problems in performing daily routine activities.

Good Material Quality:

The scaler has to be designed from good quality material that is lightweight and corrosion-free. Hence stainless steel products are the best quality products available in the healthcare market. The instruments are lightweight and robust. Another thing to keep in mind while selecting an instrument is that the instrument should not be made of a material harder than the tooth's enamel.

Lightweight Instrument:

The dentistry instrument should not fatigue the operator's arm while in use. The scaler may be in the operator's hand for quite some time if the calculus deposits are heavy. Hence scalers and curettes need to be lightweight to avoid fatigue. Heavy instruments require more excellent muscle activity and pinch force.

Handle Shape:

The instrument handle should be round and tapered. Tapered handles use lesser arm and pinch force in comparison to untapered handles. Hence, the handle of the instrument has to be tapered to avoid muscle fatigue.

All in all, the bottom line is that the operators should use tools that fit in their hands. Also, are efficient, versatile, comfortable, effective, and long-lasting.

Stainless Steel - Ideal Material for Instrument Manufacturing:

Instruments made from stainless steel are lightweight and durable; other than that, many other favorable stainless steel properties make it ideal for instrument manufacturing. Stainless steel is corrosion-resistant. It has high tensile strength, is extremely durable, has good formability, and is easy to fabricate. Besides that, stainless steel is low maintenance and has an aesthetic appearance, and above all, it is very environmentally friendly. It is reusable and hence is the best material for surgical instrument manufacturing.

Instrument Maintenance:

All surgical instruments need maintenance to ensure that they are fit for purpose and in good working condition before use. Other than that, instruments require time to time inspection to ensure that they are sharp, efficient, and always ready for use.

Dental surgical equipment should not be overused. Overuse causes their blades to get dull and their locks to malfunction.

GerDentUSA Inc. offer customization of dentistry instruments to our customers. Our expertise in surgical equipment manufacturing and supplying has made us one of the best in today's healthcare market. Some practicing doctors find traditional instruments hard to work with.

Hence they are encouraged to come up with innovative designs for dental surgical equipment that, in the end, will benefit the healthcare industry today and in the future of denstistry.